The bike was quite stable on the centre stand, with an axle stand under the final drive, but I was still anxious to get the wheels back under it in case I bumped against it and toppled it off the stands.

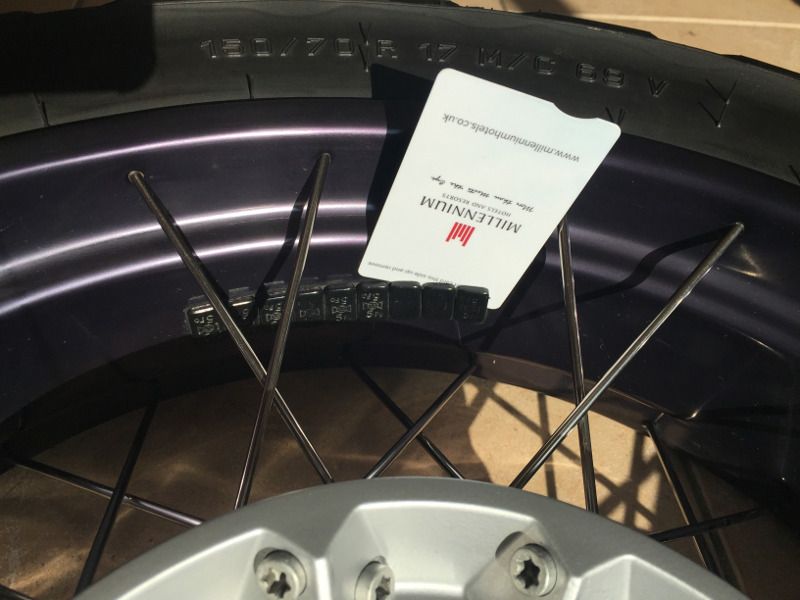

I started by removing the balancing weights from the front wheel. I wedged a plastic key-card from a hotel between the weights and their adhesive backing, and prised the weights off.

I then used my thumb to "roll-up" the adhesive tape and pull it off the wheel. I used denatured ethanol to remove any residue left by the adhesive. I found that kneeling on the ground, leaning over the wheel was a bit awkward, so I mounted the wheel on my static wheel balancer, so I could sit on a chair and just rotate the wheel as I worked my way around it. I'd already treated the wheels with IRON to remove any inorganic contamination (mainly brake dust), but I found two or three speckles of tar on the rim, so I auto-clayed the rim, rinsed it, then wiped it down with PREP. I applied RIM to the rim, hub and each spoke.

As I mentioned in

my thread about a rear wheel balancing adapter, the rear wheel of the R1150GS won't fit on a standard static balancer without an adapter. After a bit of thinking and research, I found that a Trend B41 bearing (a spare part for a Trend woodworking router) was an ideal adapter to fit the rear wheel on the static balancer:

I mounted the rear wheel on the static balancer and gave it the same treatment as the front wheel. After giving the first coat of RIM an hour to cure, I gave each wheel a second coat.

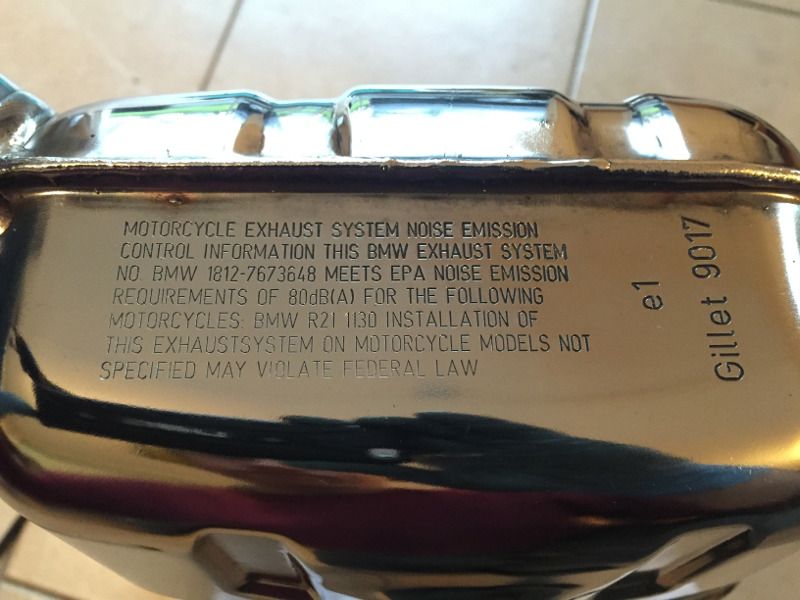

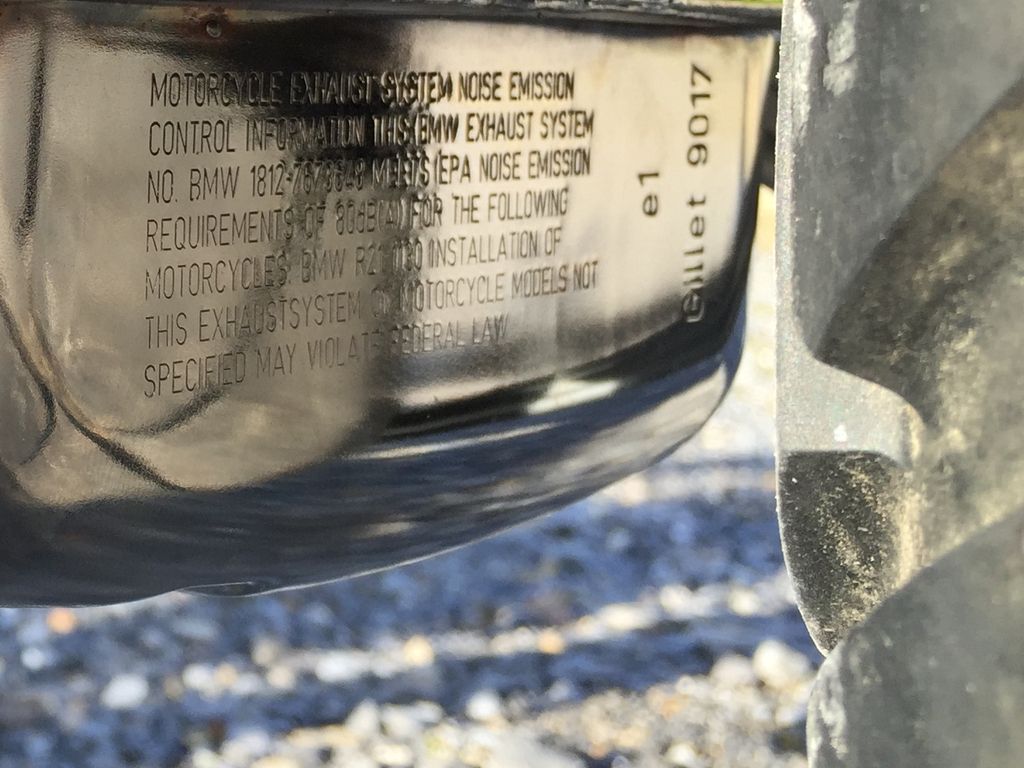

Finally, I moved on to the exhaust. This was the part of the detail that I'd been looking forward to the most. The downpipes were tarnished from heating, so polishing them was going to make the biggest visual difference to the bike. This is what the exhaust looked like before I started:

The muffler wasn't discoloured or tarnished in any way, it was just very tar spotted:

When I asked Rich from Polished Bliss if the tarnishing could be removed or if it was permanent, he told me: "Bluing arises when Chromium (either solid or a coating) becomes really hot and starts to oxidise" and assured me that it could be removed with a strong metal polish, such as Raceglaze Alutech. He also said that if I sealed the chrome with RIM after I'd corrected it that it would prevent them from oxidising again, even if they got very hot. Rich had suggested that polishing the exhaust by hand would be easier, so I started with a hand-polishing pad and Raceglaze Alutech. After about five hours, I had progressed about four inches down the first pipe:

The muscles in my hand and forearm were starting to cramp and I decided that no matter how awkward it was with a dual-action machine polisher, it couldn't be any harder than polishing by hand. After five minutes with a cutting pad on the DA and Raceglaze Alutech, I'd made more progress than I had in the previous five hours by hand. Only then did it occur to me that when Rich said it might be easier by hand, he would have assumed that the exhaust was still on the bike, making it difficult to get access with the DA! Another two hours of polishing had removed most of the discolouration with only a few stubborn, darker patches near the exhaust ports:

It took me another day and a half with the DA polisher to remove all the discolouration from the whole exhaust system, including the catalytic converter, and then remove the fine polishing marks using Meguiar's NXT All Metal Polysh to bring up the mirror finish I was looking for. I destroyed three polishing pads in the process:

This is what the two smaller ones looked like when they were new:

But I think the results were worth the effort:

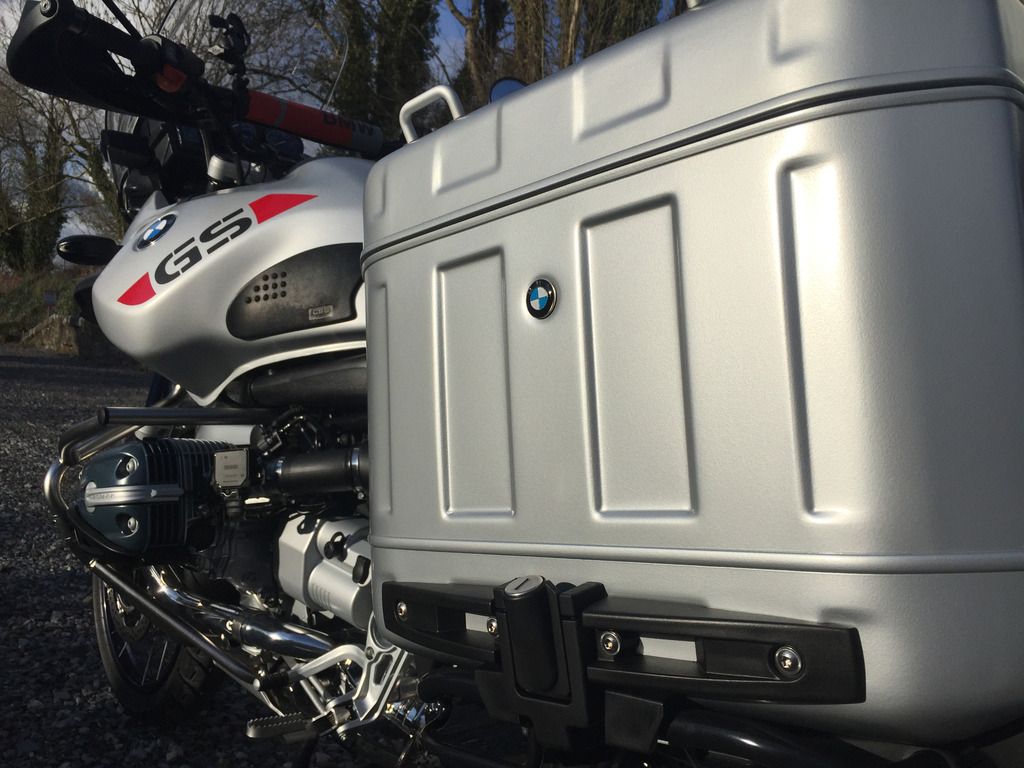

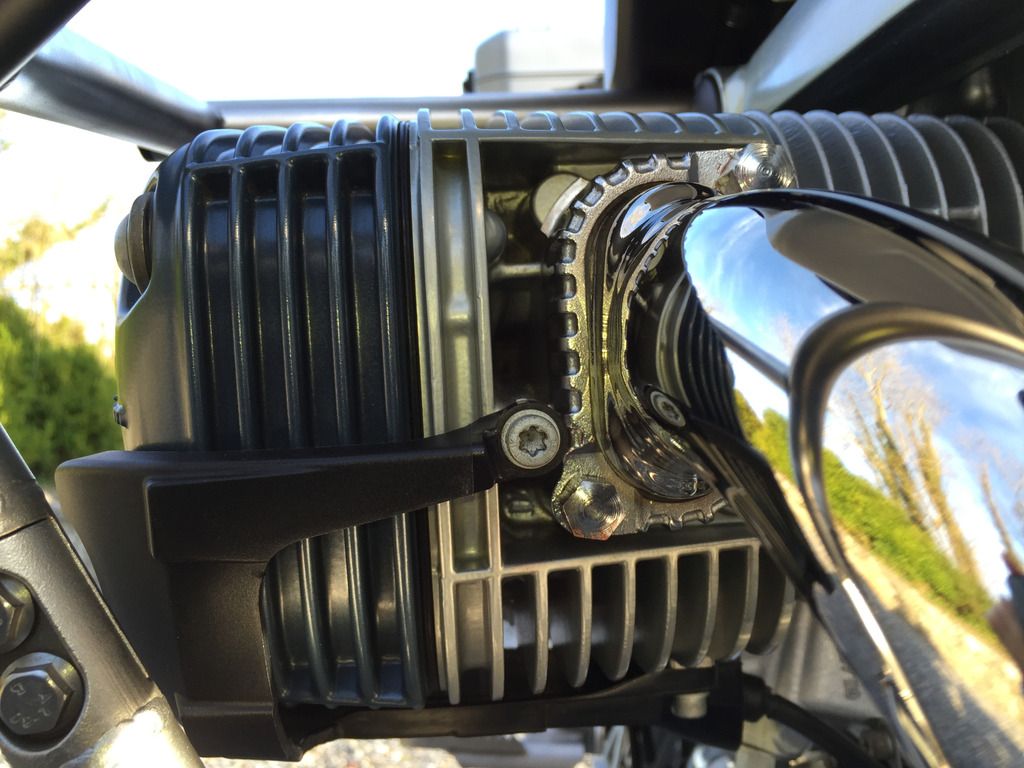

I gave the whole exhaust system two coats of RIM to protect the finish I'd achieved. I then started the fun job of re-assembling the bike, applying copper grease to every nut and bolt. I fitted new spark plugs and oil filter and filled the engine with oil:

I took a photo after fitting each part to the bike and made a time-lapse video. Unfortunately, the picture quality isn't great because I didn't realise that there was something wrong with the camera:

<iframe width="560" height="315" src="https://www.youtube.com/embed/BhQM7s_Oxcw" frameborder="0" allowfullscreen></iframe>

When I tried to start the bike, it would turn over, but wouldn't start. After a few minutes of trying, I removed the tank to have a look underneath and found that I'd left something unplugged (the motronic, I think).

After getting it started, I loaded it up into an Ifor Williams boxvan:

I took it to Ballyglunin railway station to take some nice photos of it. Ballyglunin railway station was used as "Castletown" railway station during the filming of The Quiet Man, with John Wayne in 1951.

When I added it all up, I spent 220.5 hours over four months working on the bike. It was a huge effort and at times was nearly overwhelming, but I'm glad I did it because I now know the bike has the best possible protection that can be applied to it.

Below are the photos in Ballyglunin railway station of the final result:

Total hours: 220.5

.

.

.

. amazing !

amazing !