ralphy

Registered user

Having finally extracted the remaining studs from my cylinders:

https://www.ukgser.com/forums/showthread.php/551825-Manifold-stud-removal-what-else-can-be-done/page2

It's made me wonder whether to fit replacement studs & nuts, or would fitting bolts be a better option???

Also...

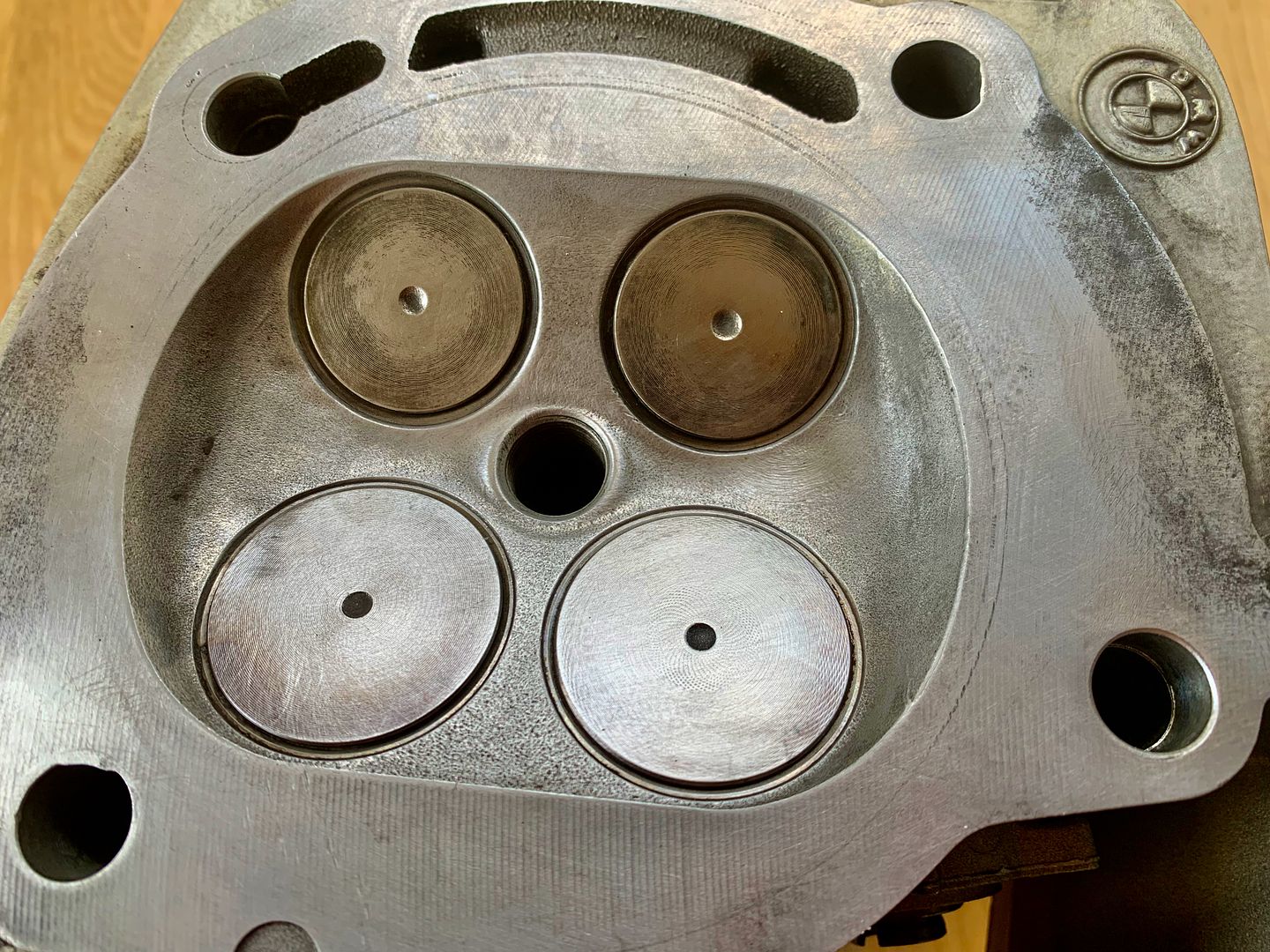

Having taken the cylinder off I was presented with this:

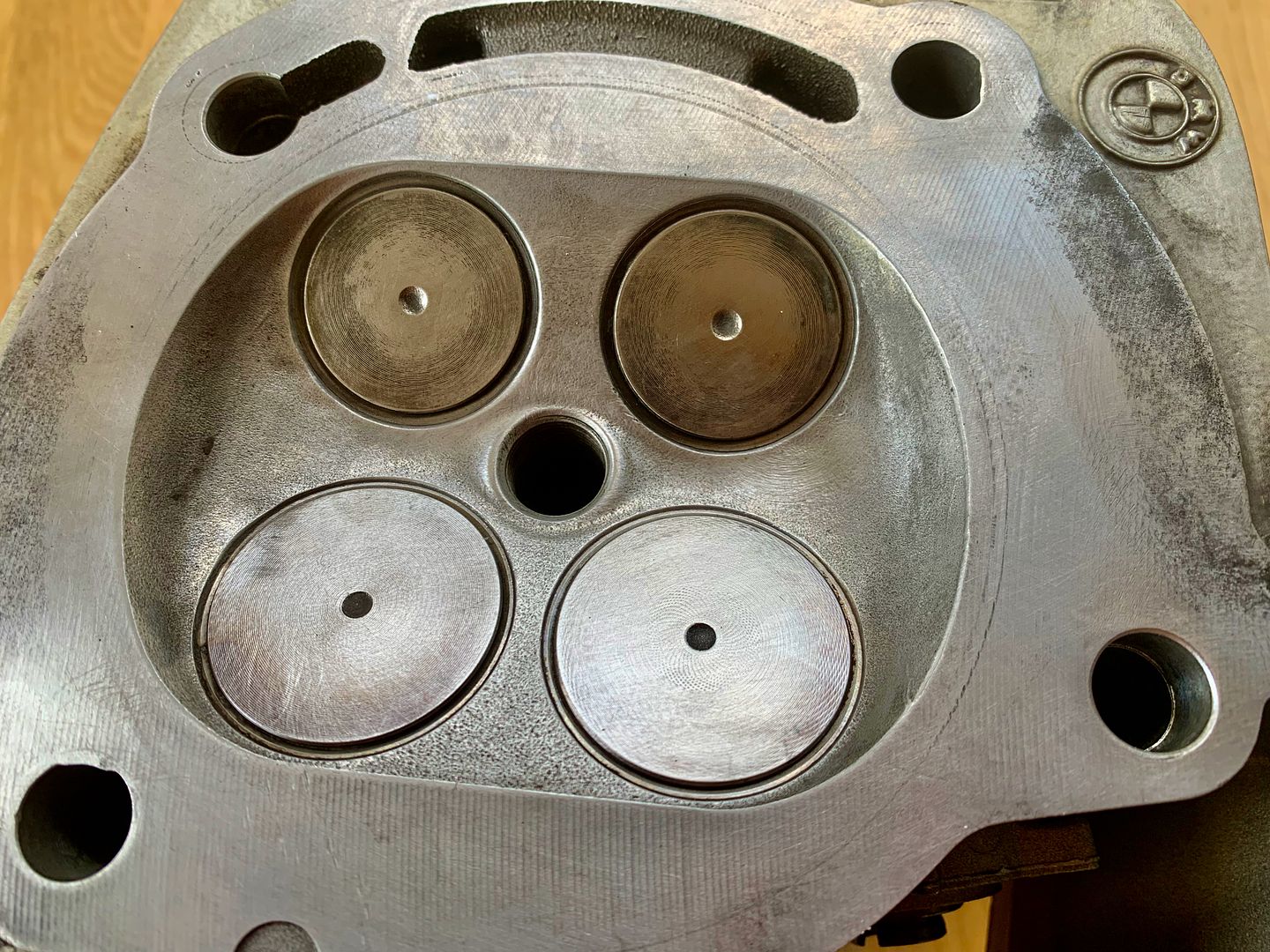

So I cleaned it up:

But would it be necessary to take the other cylinder off to clean it up or would leaving it alone have some negative effect with one clean cylinder and the other one dirty???

Thoughts on both q's please.

R

https://www.ukgser.com/forums/showthread.php/551825-Manifold-stud-removal-what-else-can-be-done/page2

It's made me wonder whether to fit replacement studs & nuts, or would fitting bolts be a better option???

Also...

Having taken the cylinder off I was presented with this:

So I cleaned it up:

But would it be necessary to take the other cylinder off to clean it up or would leaving it alone have some negative effect with one clean cylinder and the other one dirty???

Thoughts on both q's please.

R