Hello all,

At the end of this month another project which I dont have time for is coming to live in a garage that doesn't have space for it.

I'd intended to add an AH to the GS log book collection at some point, but this one came up (as they often do) at a really inconvenient time. However, the price was right and given plans so is the condition. Some much needed flexibility from the vendor sealed the deal.

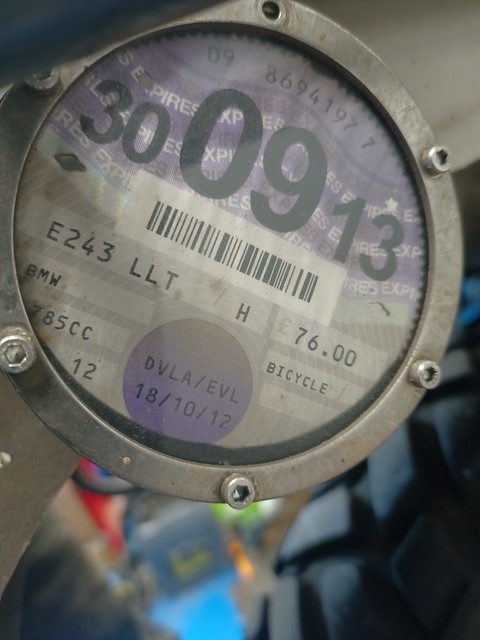

It has no service history. The only thing I do know is it's an immigrant but has lived here legally for some years now.

I don't know if it runs as a start hasn't been attempted.

It is complete and comes with BMW plastic cases.

It's going to be a green laner. It doesn't need to carry anything other than day supplies.

A full refurb is definitely on the cards with the engine and drive train to go back to Mike for rejuvenation.

However.....

I'm really rather taken with it so I'll see if I can get it to start following some sense checks then a fluid change.

If that goes well. MOT and well, ride it for a bit.

The list looks something like this at the moment:

Change the front wheel to a tubed 21" typical 36 spoke rim using a wheel I already have.

320mm brake conversion.

Caliper swap.

Replace the mudguards with new modern stuff

LED lighting conversion

Frame powder coat and strengthen.

Fit an 18" tubed rim from a mono PD (already have).

Construct new or hack about the existing rear subframe to remove surplus metal.

Single seat conversion.

Fork swap with RM125 conventional forks (already have).

Paint the tank

General cosmetics.

This is going to be evolution rather than revolution.

It's entirely possible that this won't get started for sometime. I know nothing about these bikes so starting the post early so that I can begin working through the complications that inevitably arise. Stupid questions guaranteed.

Two other bikes need my immediate attention before I dig too deeply into this one, so if there are any signs of mechanical problems or it won't start it will have to wait.

A few pics here:

https://flic.kr/p/2ocYXMu

At the end of this month another project which I dont have time for is coming to live in a garage that doesn't have space for it.

I'd intended to add an AH to the GS log book collection at some point, but this one came up (as they often do) at a really inconvenient time. However, the price was right and given plans so is the condition. Some much needed flexibility from the vendor sealed the deal.

It has no service history. The only thing I do know is it's an immigrant but has lived here legally for some years now.

I don't know if it runs as a start hasn't been attempted.

It is complete and comes with BMW plastic cases.

It's going to be a green laner. It doesn't need to carry anything other than day supplies.

A full refurb is definitely on the cards with the engine and drive train to go back to Mike for rejuvenation.

However.....

I'm really rather taken with it so I'll see if I can get it to start following some sense checks then a fluid change.

If that goes well. MOT and well, ride it for a bit.

The list looks something like this at the moment:

Change the front wheel to a tubed 21" typical 36 spoke rim using a wheel I already have.

320mm brake conversion.

Caliper swap.

Replace the mudguards with new modern stuff

LED lighting conversion

Frame powder coat and strengthen.

Fit an 18" tubed rim from a mono PD (already have).

Construct new or hack about the existing rear subframe to remove surplus metal.

Single seat conversion.

Fork swap with RM125 conventional forks (already have).

Paint the tank

General cosmetics.

This is going to be evolution rather than revolution.

It's entirely possible that this won't get started for sometime. I know nothing about these bikes so starting the post early so that I can begin working through the complications that inevitably arise. Stupid questions guaranteed.

Two other bikes need my immediate attention before I dig too deeply into this one, so if there are any signs of mechanical problems or it won't start it will have to wait.

A few pics here:

https://flic.kr/p/2ocYXMu