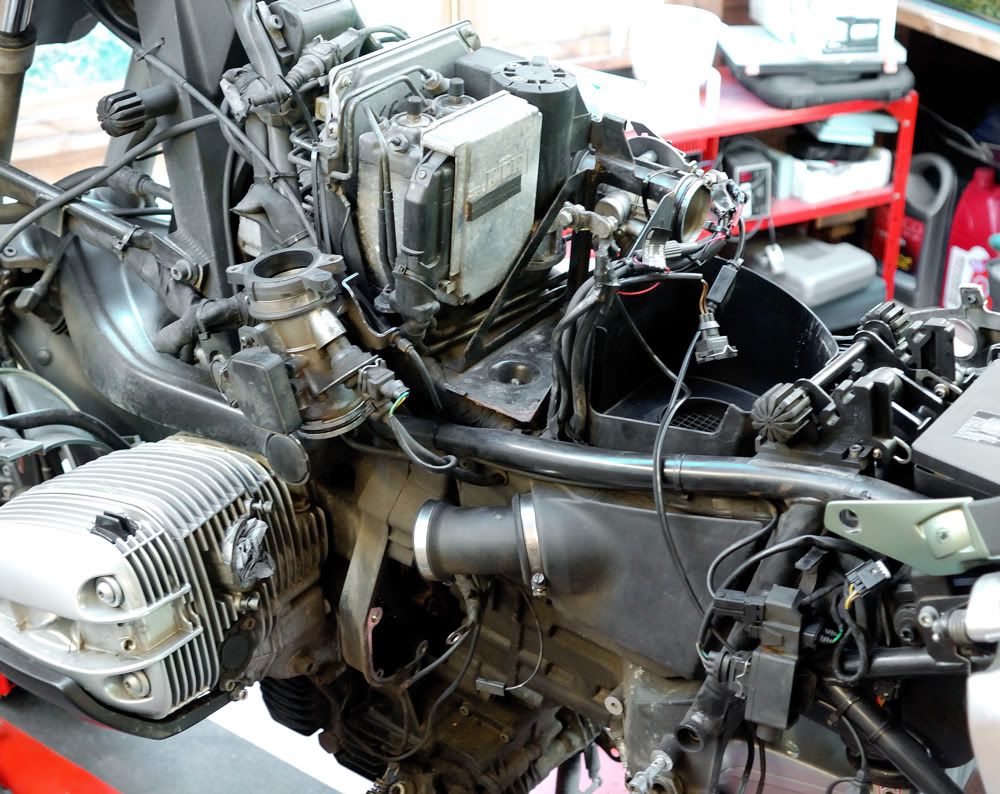

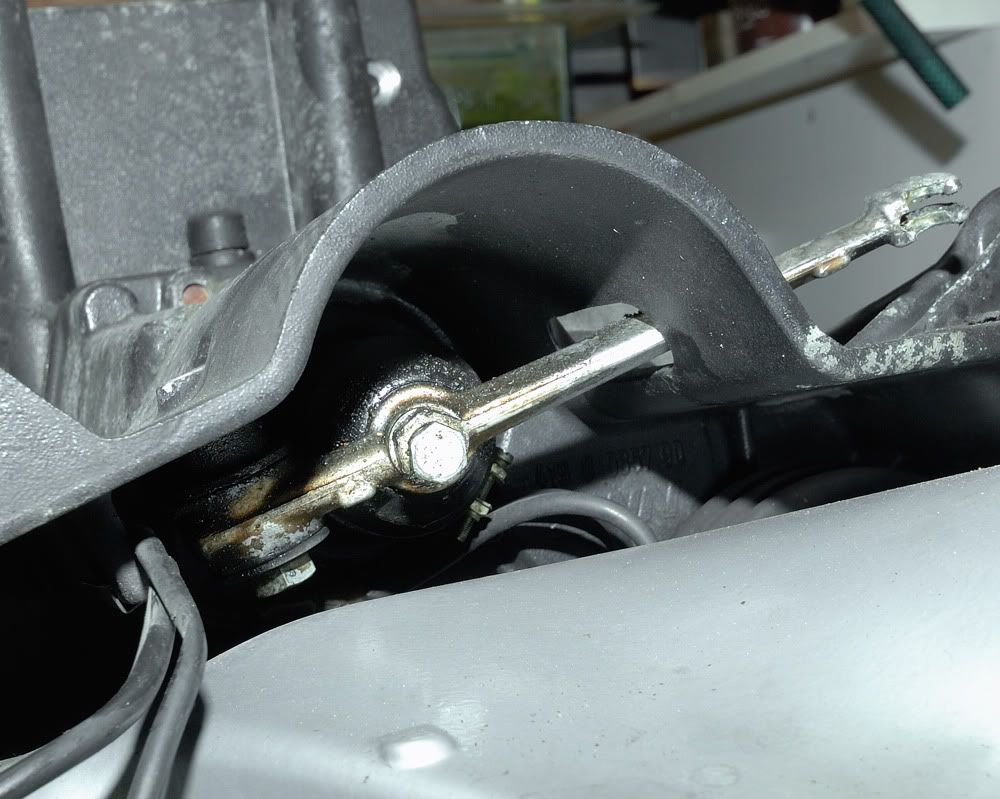

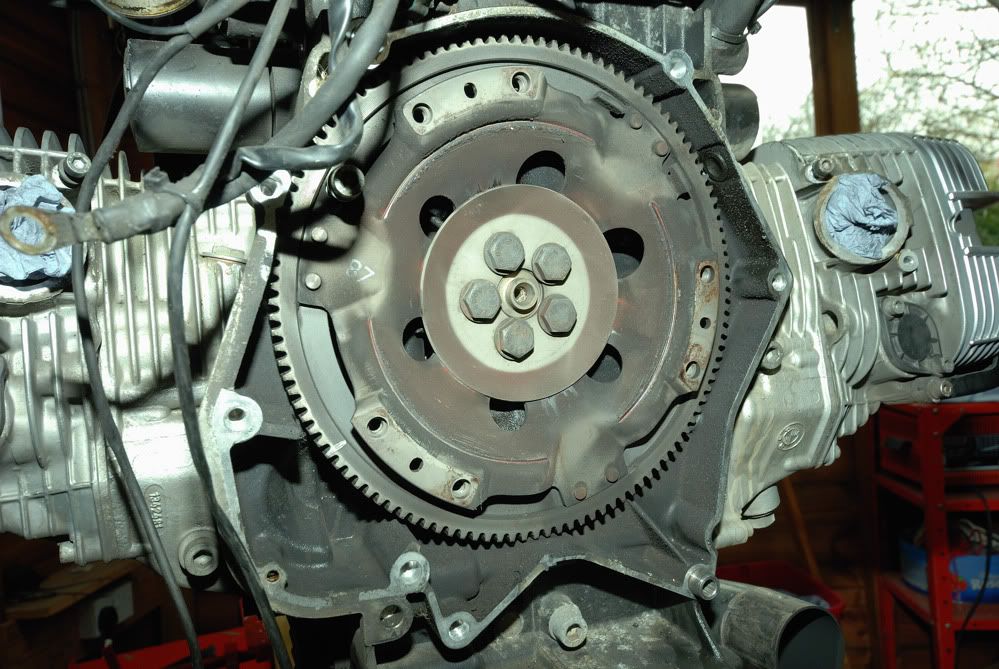

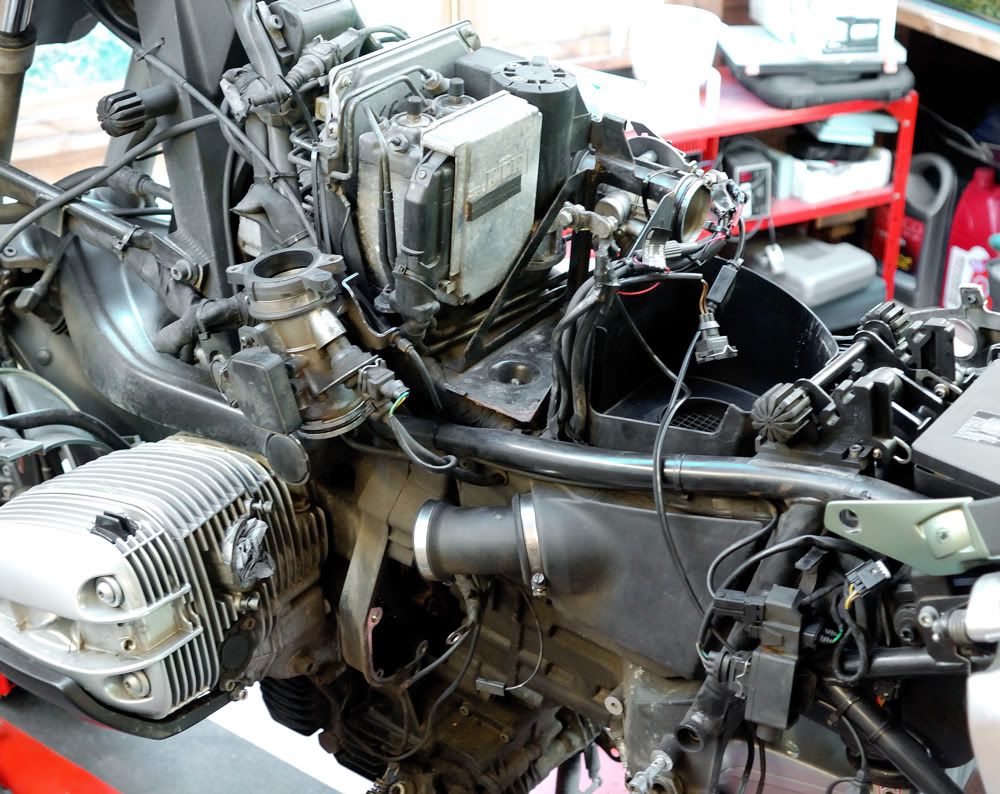

I'm about to lift the rear frame to get access to the box for a clutch change, but it wont move much, I have found two bolts under the ABS that need to be removed, any tips on how to remove abs without disturbing it to much so no bleeding reqd???

All help much appreciated

All help much appreciated